Beer is all about biochemistry. There are four ingredients you need to use for different types of beers. So how can you produce various kinds of beers using the same water, malted grain, hops, and yeast? The answer is that it involves a series of biochemical reactions. You will find all the answers in this article.

First of all, you need a sugar source. Although in wine, you need to use natural sugars, in beer, you will have to use malt. This is because you need to use fermentation to produce beer from malt. This should help you differentiate beer from wine. Here is the complete detail of the ingredients and the processes involved.

Table of Contents

ToggleStep 1: Malting (The use of malt to extract starch)

Grains or seeds from plants belonging to the grass family are starch sources. Usually, you use barley grains as malt. The first step involves soaking the barley grains in water. This process is known as malting. The primary purpose of malting is to extract starch from the soaked grains, which also sprouts after some time. Sprouting is also necessary when you need to use this starch in the next step since it produces starch-digesting enzymes.

The following crucial step is drying the barley. The temperature used for this process is responsible for deciding upon the type of malt to form. For instance, a high temperature to dry the barley will result in darkened malt, and a low temperature will result in light-colored malt. The type of malt you need depends on your requirements. This is because the malt’s quality will affect the beer’s color and flavor. Thus, you need to give special attention to this step.

Step 2: Mashing (Adding hot water to the malt)

The brewers add hot water to the malted barley to activate temperature-dependent enzymes. This process is known as mashing. It is no longer a secret that enzymes are proteins in every living organism. These enzymes work best at an optimum temperature, each with its different optimum temperature level.

Thus, in this process, brewers use temperature-dependent enzymes that work properly at high temperatures. Brewers add hot water between 60°C and 70°C for 60 minutes. The enzymes produced in the malting process are in the inactivated form. These enzymes will convert complex starch into simple sugar through a biochemical process known as saccharification.

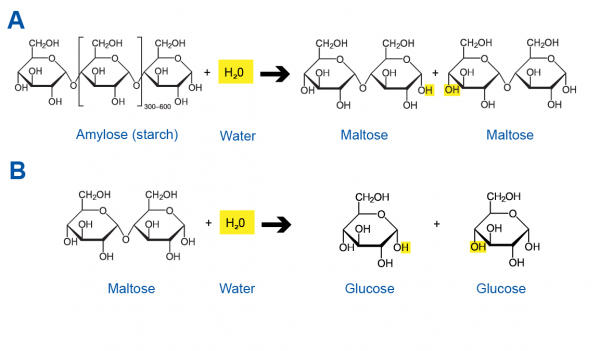

After extracting sugar from the malted barley, the following step will involve you filtering out the mixture, which is no use now. The remaining sugary liquid is called wort. This image will be helpful in understanding:

The above diagram shows the chemical reaction of starch and water to form maltose (A) and the chemical reaction of maltose and water to form glucose (B).

In each step, you have to give special attention to the ingredients because any change in their composition can alter the color or flavor of the beer.

Step 3: The Hops

The following step involves brewers adding hops to the wort. If you are unsure what hops are, these are buds of flowers belonging to the hemp family. These buds have resins, the chemical compound that gives bitterness and aroma to beer. Next, brewers boil the wort to extract resins from the hops. In the process, hops become soluble in the wort.

The beer’s flavor is all about timing. It depends on when you add hops into the boiling wort. For instance, if you add hops early, it will make the beer bitter in taste. However, if you add it later, it will improve the beer’s aroma. The number of hops also contributes to the determination of the flavor.

You probably know that resins contain alpha acids, beta acids, oils, and tannins. In addition, there are various hops with different properties of alpha acids, beta acids, oils, and tannins. Thus, it boils down to choosing the ingredients accurately according to the beer’s flavor you need.

All the ingredients of resins have different functions. For instance, alpha acids impart bitterness, whereas oils provide aroma. On the other hand, the tannins and beta acids are filled with disinfectant properties.

Step 4: Fermentation

The last step is the use of yeast, which is a unicellular organism or a single-celled organism. Yeast is a type of fungi, and it works as a biochemical regulator. With yeast, you can convert glucose into alcohol and carbon dioxide. Thus, yeast will break down glucose into alcohol and carbon dioxide, which is a byproduct, through fermentation.

Fermentation is very commonly used in bakeries for baking products, which makes people familiar with the process. Since yeast works as a chemical regulator, you need to separate it after the reaction has completed. However, you can still reuse it in the following reaction.

Apart from performing its primary function of converting glucose into alcohol and carbon dioxide, it also significantly impacts the beer’s flavor. Various yeasts have different metabolisms; thus, each yeast used will give its specific flavor to the beer. In addition, since their metabolism is different, their byproducts will also differ. This may include esters, fuse, alcohol, or phenol, giving their distinct taste and flavor to the beer.

Usually, two styles or procedures of yeast fermentation are in use. One is top-fermenting (also called Ale yeast), and the other is bottom-fermenting (lager yeast). For example, Saccharomyces cerevisiae, a common yeast used in bakeries, is a top-fermenting yeast, and it likes to work at high temperatures up to 25°C.

Saccharomyces pastorianus is a bottom-fermenting yeast that works accurately at a lower temperature. As a result, it produces drier beer, which is favorable for the Tasmanian weather. Fermentation time for an Ale is 2-14 days, while lager takes several months.

I am a passionate beer connoisseur with a deep appreciation for the art and science of brewing. With years of experience tasting and evaluating various beers, I love to share my opinions and insights with others and I am always eager to engage in lively discussions about my favorite beverage.