Embarking on a journey to take a break from alcohol can be a significant step

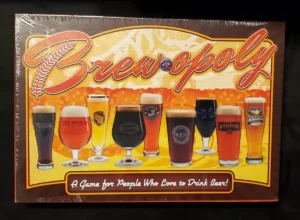

Embarking on a journey to Paris or any other French city as a beer aficionado

In recent years, there has been a growing interest in natural and eco-friendly pest control